KDT KN-3409DE/KN-3612DE Flat Bed CNC Router

Experience ultimate production capabilities with our system, offering bed sizes of up to 3700mm x 1830mm. Choose from 10 or 18 spindle drill head options and benefit from fast change carousel tool changing. With a powerful spindle and gantry setup, along with auto nest push-off functionality, safety features including a fence and auto shutoff beams are included for added peace of mind.

KN-3409DE

- 2850mm x 1250mm working table size

- 10 or 18 Drill head options

KN-3612DE

- 3700mm x 1850mm working table size

- 10 or 18 Drill head options

KN-3713DE

- 4260mm x 2150mm working table size

- 10 or 18 Drill head options

Features

Technical Data

| KN-3409DE | KN-3612DE | KN-3713DE | |

| Working area of Y and X axes | 2860 mm x 1260mm | 3700mm x 1800mm | 4260mm x 2150mm |

| Z Axis stroke | 150mm | 150mm | 100mm |

| Max Traverse speed | 100m/min | 80m/min | 80m/min |

| Capacity of vacuum pump | 1 X 244m³/hr | 2 X 244m³/hr | 488m3/hr |

| Vacuum table zones manually controlled | 7 zones | 7 zones | 6 zones |

| Automatic tool height measuring | Standard inclusion | Standard inclusion | Standard inclusion |

| Transmission for X and Y axis | helical rack and pinion | helical rack and pinion | helical rack and pinion |

| Transmission for Z axis | ball screw | ball screw | ball screw |

| Air cooled spindle – 3000-18,000 | 12 kw | 12kw | 12kw |

| Auto linear Toolchange | 12 position Rotary | 12 position Rotary | 12 position Rotary |

| Dust hood connection diameter | 200 mm | 200 mm | 200mm |

| Weight | approx. 4000 kg | approx. 5000kg | approx. 5500kg |

| Independent drills | 10 std , option 18 | 10 std , option 18 | 10 std, option 18 |

See the KN-3409DE in Action

Stable heavy Machine Frame

Everything on a CNC machine relies on the design, strength and rigidity of the machine frame.

160mm x 160mm x 8mm thick steel beams are the key around which the frame is built and the guides mounted.

It’s precision welded, then machined on a 5 axis machining centre. Construction normally reserved for far more expensive CNC’s and is fundamental to accuracy and long life precision.

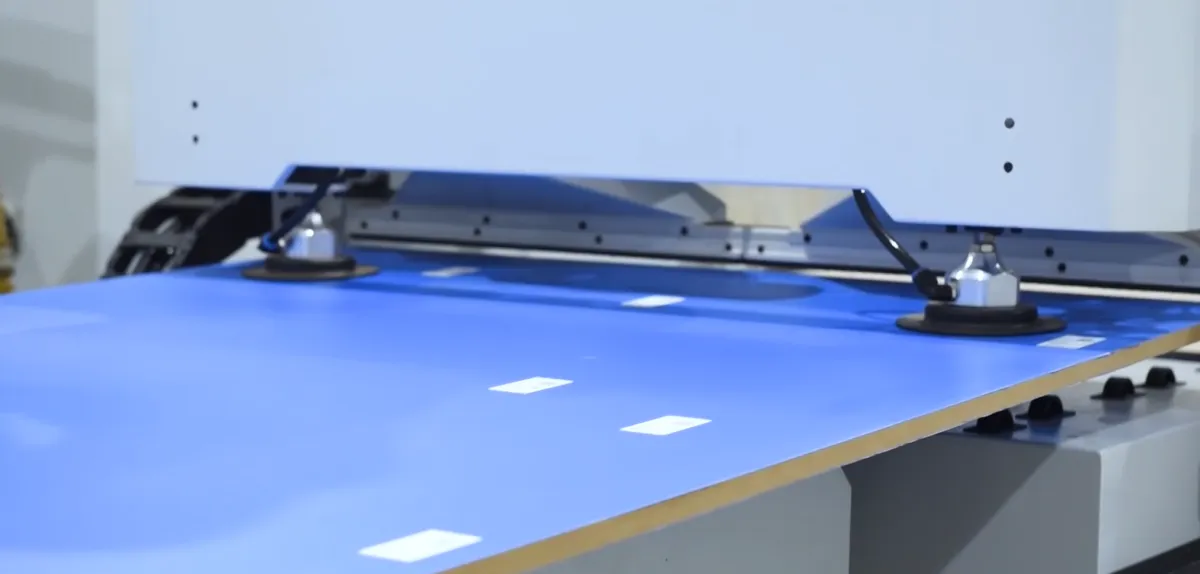

Strong and reliable vacuum

3409DE 1 X 244 CUBE PUMP

3612DE 2 X 244 CUBE PUMPS

Poor vacuum frustrates the operator with wasted panels and time.

Superior table design with a large very open vacuum chamber area that is part of the machine frame and significantly improves vacuum distribution.

BECKER pumps ensure reliability and performance

Both models have 7 vac zones

– selected from the front of the machine.

The moveable pneumatic stops have safety sensors should a stop not retract.

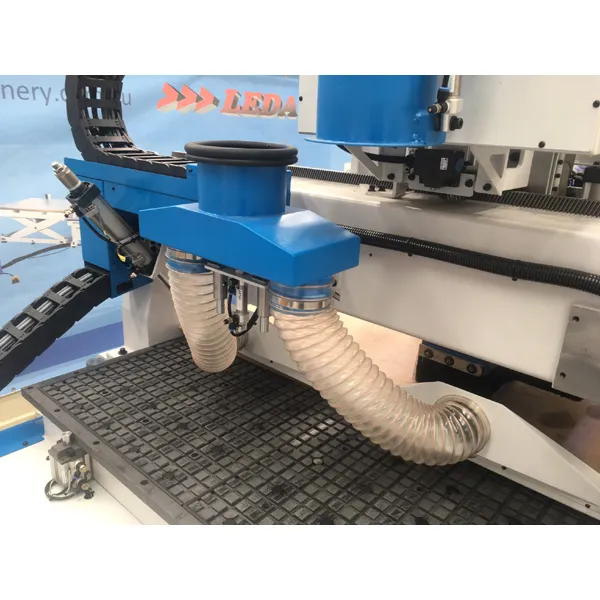

Auto loading arm - standard

Auto vacuum loading of new panels is built in ready to add the optional scissor lifts.

Combined with auto aligning arms this is a huge time and labour saver.

Scissor lift choices

The optional scissor loading tables allow you to upgrade to auto loading at any time. The larger table is twin scissor, smaller single scissor.

Both feature auto height sensing and raising.

OPTION labelling at infeed

Auto nest push off – a huge productivity boost.

Smart unloading pusher with built in extraction moves your completed nest to a sorting table. You can immediately load a new panel and commence your next nest and effectively double your output.

We can supply a simple static table – or KDT have a clever driven outfeed table option with extraction and light sensor control – perfect if using JIT labelling.

Superior Gantry design.

The best drives, guides and cables

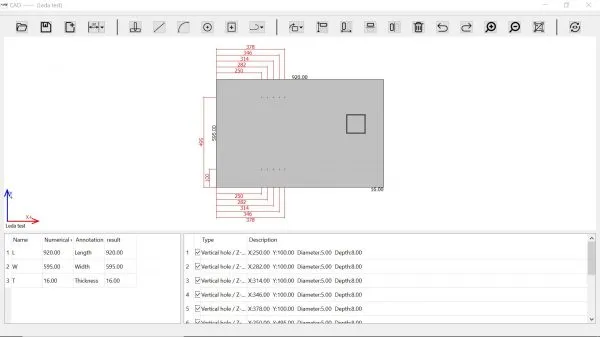

CAD Software included

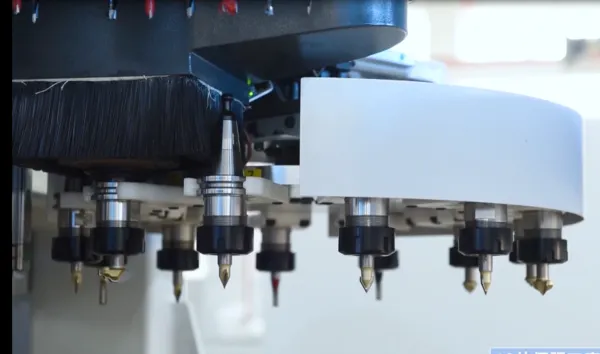

Linear tool change

12 servo ( very fast) Rotary tool change travelling with the Gantry.

Auto Tool length measuring included.

10 or 18 drills

Powerful Electro Spindle

Operator > Machine Interface PC with cooling for the Australian summer!