KDT KE-365 Edge Bander

Experience simplicity, compactness, and outstanding value with our solution. Featuring a Colour Touch Screen with PLC Controller for intuitive operation, along with a heated fence, twin end saws, top and bottom radius trimming units, profile scrapers, and buffing capabilities. Choose from three feed speeds of 15/19/23 M/min for versatility and efficiency.

Features

- Full safety covers

- Touch screen Controller

- Quick set-up for strip thickness

- High feed rates – 15 / 19/ 23metres/min.

- Feed jogging button to assist setting up.

- Pneumatic shut-off gate on glue roller.

- Front and rear tape allowance adjustment from touch screen.

- Electronic ‘line control’ setting and monitoring of workpiece positions

- 75mm dust exhaust hoses for efficient extraction.

- Large windows and lights for better visibility.

- Four independent pneumatic pressure rollers

- Pneumatic gate prevents panels being fed too soon

- Powered height setting on pressure beam

- Extra solid panel support rail running on 50mm diameter rails

- High precision ‘THK’ slide ways on cut-off saws with auto lubrication. Pneumatic saw tilt

- Efficient high frequency direct drive motors on saws and trimmers.

- Pneumatic blowers on scraper tracer wheels to keep swarf from affecting accuracy.

- Buffers mounted on 50mm round bars – will not flex under load.

- Heavy weight machine @ approx. 1300kgs.

- Length of machine – 3940mm.

- Panel length 120mm >. Panel Thickness 10-60mm. Panel width 80mm >

Technical Data

| Panel feed speeds | 15, 19 and 23 m/min |

| Total power | 9.06 kW |

| Length 365 | 3940 mm |

| Edge thickness | 0.4 – 3.0 mm |

| Panel thickness | 10 – 60 mm |

| Panel thickness when premilling | 40 mm |

| Weight 365 | 1300 kg |

| Minimum panel length | 150 mm |

You're in Control

The KDT touchscreen is user-friendly, setting new standards in control. You can easily select functions, adjust feed track speeds, move the beam up or down, and control glue temperature. Additionally, you have the option to activate the front, rear, or both saws.

The interface is clear, simple, and highly effective. Alongside, the machine offers comprehensive parameter setting functions, diagnostics, and fault-finding capabilities. If issues arise, the system provides detailed reports, reset methods, and helpful ‘fix it’ guides to simplify troubleshooting and maintenance.

Handle the Heaviest Tapes

800mm diameter supported by a massive 60mm dia. column – even the heaviest tape coils stay perfectly aligned with the infeed and rotating smoothly

Panel Feed is Precise, Reliable and Foolproof

Simple and reliable alignment and feeding mechanisms ensure that panels travel seamlessly through the workstations. The machine features an 18mm heated infeed fence, which effectively removes moisture and warms panel edges, thereby improving bonding results.

Additionally, a pneumatic stop mechanism prevents a second panel from entering too soon. Furthermore, electronic ‘line control’ replaces micro-switches for enhanced efficiency.

Handle the Heaviest Tapes

Guides and feed rollers are securely mounted on twin 10mm steel plates. An oversized pneumatic guillotine cleanly shears even the heaviest tapes.

The machine is equipped with four pressure rollers, each supported by its own pneumatic cylinder. The first driven roller is hard chromed, ensuring durability and efficiency. Rollers 2 and 3 are tapered to apply extra pressure at the top and bottom, while Roller 4 serves as the final guarantee of a perfectly tight edge.

Additionally, the pressure rollers adjust as a set to accommodate different tape thicknesses, providing versatility and precise performance.

The Driven Track

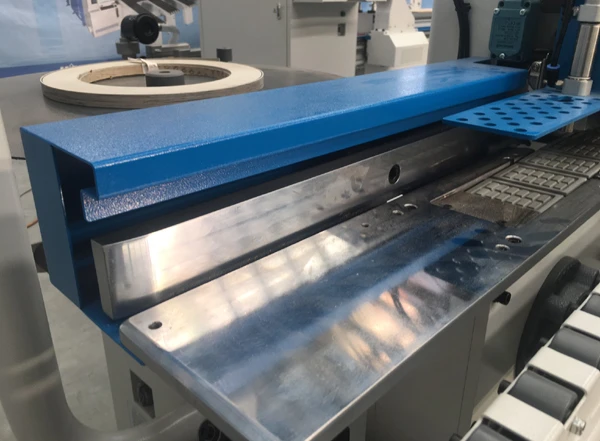

Well Supported

The 630mm panel support rail is mounted on 50mm diameter solid steel bars, which run on ball bearing roller guides. This robust construction ensures that it won’t sag, even when supporting large, heavy panels.

Smart Inverter Control