KDT KE-396JB Adjustable Bevel Edge Bander

Bevel, bevel /flat combination, edge and trim- all in one pass. Fast , easy and great bevel edge panels to deliver today’s design trends.

Features

- Full safety covers

- Touch screen control

- Lights inside safety hoods.

- High feed rates to 20 metres/min.

- Feed jogging to assist setting up.

- Pneumatic shut-off on glue roller.

- Front and rear tape overlap adjustment from touch screen.

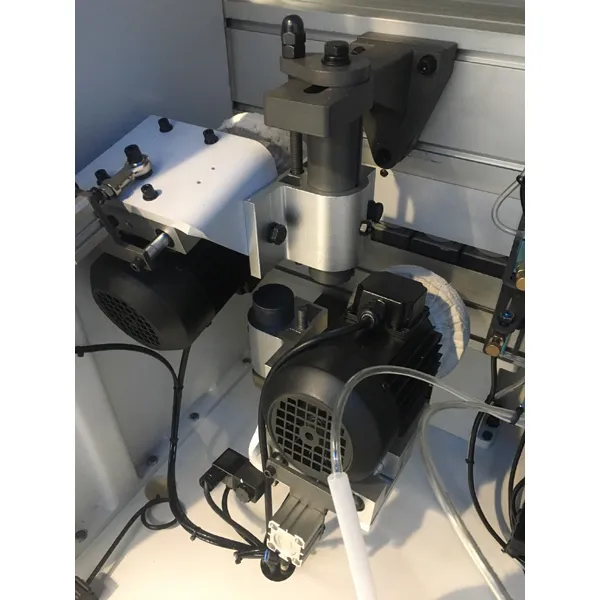

- 75mm dust hoses for efficient extraction.

- Large windows

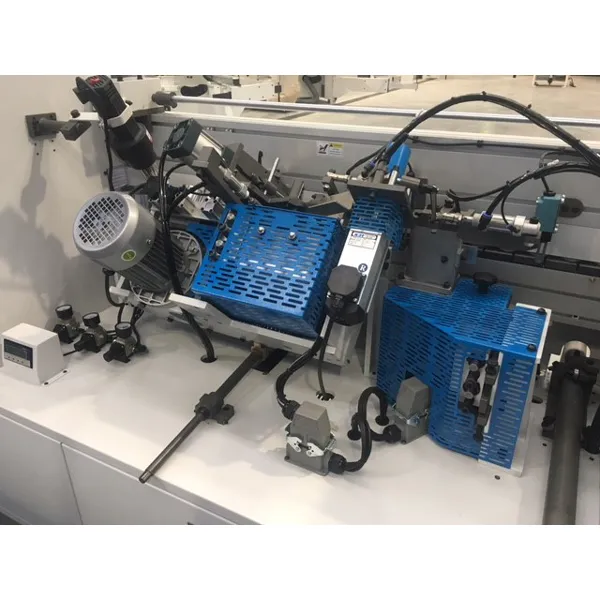

- Diamond tipped cutter heads on twin spindle milling stations.

- High precision electronic angle setting of milling and gluing bevel

- Pneumatic gate prevents panels being fed in too close

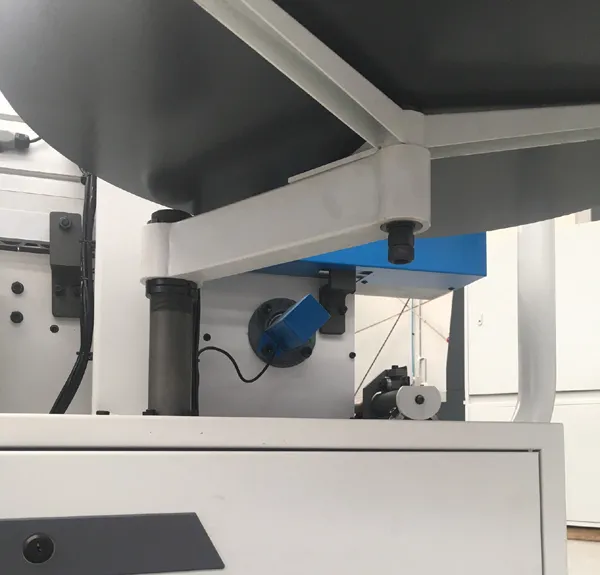

- Motorised height setting of top beam

- High precision slide ways on cut-off saws.

- Efficient high frequency belt free motors on saws and trimmers.

- Pneumatic blowers on scraper tracer wheels

- Buffers: pneumatic oscillation prevent scorching.

Technical Data

| Feed Speed | 12 – 20 m/min |

| Panel Thickness | @ 45deg. 9 – 25mm @ 2mm edge. 9-35mm normal |

| Minimum Panel Length | 150mm |

| Minimum Panel Width | 135mm |

| Edge Thickness | 0.45 -2mm for angular. 0.45 – 3mm |

| Angle Adjustment Range | 0-45 degrees |

| Overall Power | 19.88kw |

| Machine Size | 7400 x 870 x 1610mm |

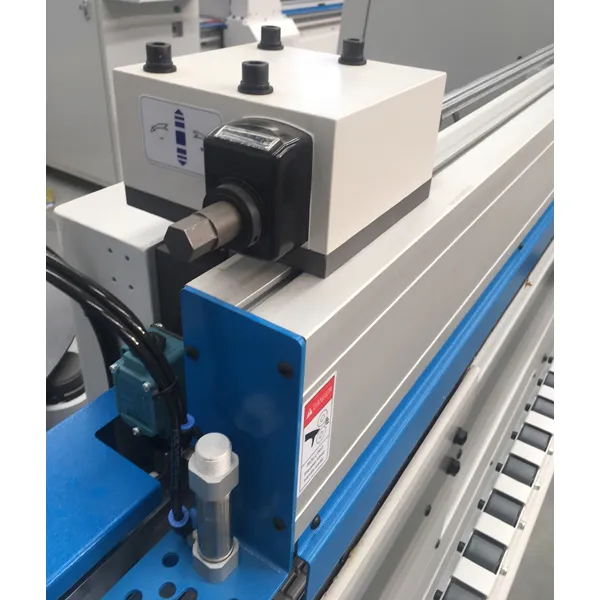

Now with top belt feed

Your absolute guarantee of precision panel tracking through the Edgebander. Perfect solution for smaller and more slippery panels

Built in strength

Wherever you look you see this

Just a few examples:

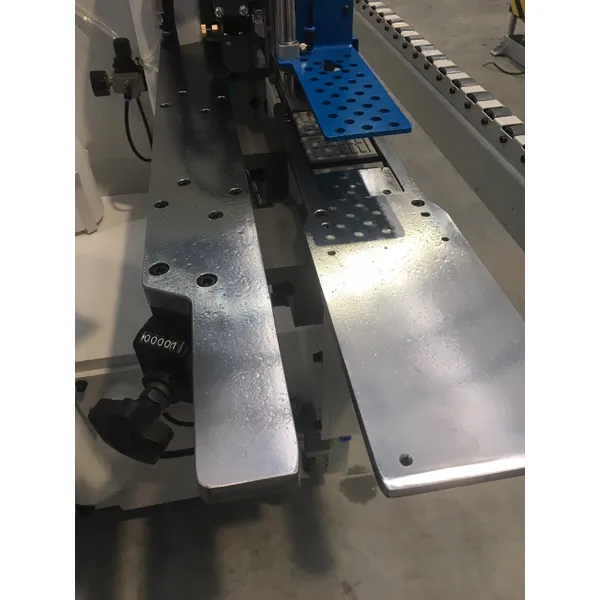

- Saws on cast iron mount

- 10mm plate steel base

- Table support rails 50mm

- 18mm thick hard chrome fence

- Buffers mounted on 50mm columns

You’re in control

The functionality and user friendly format of KDT’s touch screen sets new standards.

ICON Select all functions, the 3 feed track speeds, Up/down of the feed beam, glue temperature setting the machine to ‘standby’ etc!

Pre-program start up and shut down times.

Comprehensive parameter setting function allowing you to adjust settings –e.g. front edge overhang

Handle the heaviest tapes

800mm diameter and supported by a massive 60mm diameter column this will keep even the heaviest tape coils perfectly aligned and rotating smoothly

Perfect tape feed and application

Twin glue tank.

Multiple elements ensure quick and even heating of the glue Automatic ‘standby ‘ lowers the glue temperature to maintain colour and strength.

Independent tanks apply glue to the straight and bevel panel edges – not to the tape : really important >avoids sticky tape trimmings accumulating throughout the feed path.

Tilt angle of the second gluing station is electronically/ digitally set for total accuracy

Panel feed is precise, reliable and foolproof

Onto the feed track….

The driven track

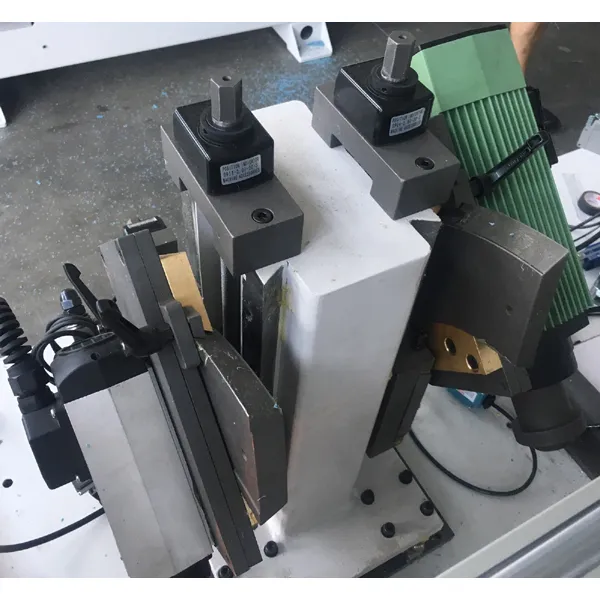

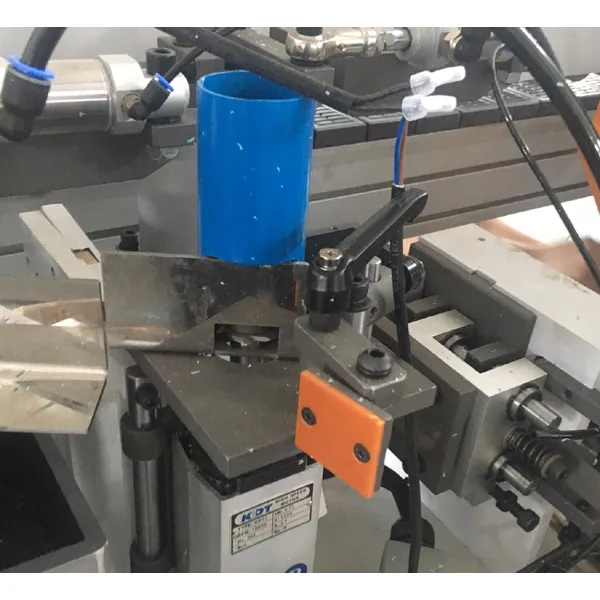

Unique twin hogging system shapes your Panel edge

The heavy duty twin vertical and bevel trimmers cleanly hog the panel edge to the required bevel angle or bevel/ vertical profile.

On very solid dovetailed tilt guides these are in a separate cabinet to isolate dust created.

High precision digital angular setting displays allow easy angle resetting.

Clever bevel cut into Tape ensures clean fold

End saws precision is guaranteed

Trimmed top and bottom ‘spot on’

Highest precision scraping

The final polish