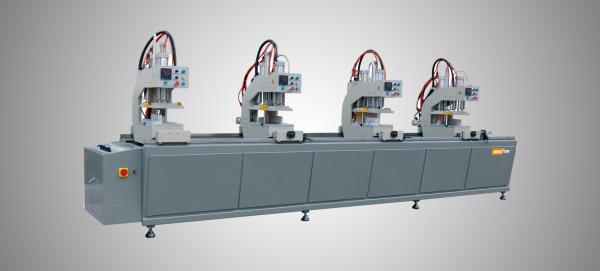

HTWA3

UPVC Window Three Head Welding Machine

The HTWA3 UPVC Window Three Head Welding Machine is a high-performance, European-style solution engineered for advanced PVC window manufacturers. Designed with a solid mechanical structure and integrated precision systems, this machine enables fast, accurate, and flexible welding operations for a wide variety of profiles.

The HTWA3 supports automatic switching between 0.2mm seamless welding and standard 2mm welding, making it ideal for both high-precision and heavy-duty window frame applications. It offers versatile welding configurations including V-welding, T-welding, cross welding, and optional H-welding, thanks to its independently pivoting heads. The integration of high-grade square and linear bearing systems, coupled with a V-shaped heating plate, ensures reliable alignment, consistent welding strength, and minimal deviation.

This model also features an ergonomic turret system for effortless adjustment across different profile types, allowing your production team to maintain efficiency while meeting high quality standards.

Advanced European-type design, built for high-end PVC window manufacturers.

Supports automatic switch between 0.2mm seamless welding and standard 2mm welding.

Capable of V-welding, T-welding, and cross welding without complex setup.

Each welding head can pivot 90° inward to perform optional “H” welding.

Ergonomic turret system for fast V-welding positioning across various profiles.

Rigid clamping system ensures minimal welding loss and high dimensional accuracy.

V-shaped heating plate delivers strong, reliable corner welds with low tolerance.

Imported square bearing system ensures precision movement during all operations.

Linear bearing system provides stability and smooth motion.

Heavy-duty mechanical base guarantees long-term durability and accuracy.

Interchangeable profile fixtures accommodate varying profile heights.

Quick-change special fixtures for enhanced corner strength and easier post-weld cleaning.

Dual-hand safety operation system.

Integrated pneumatic brake for stable, secure operation.

Variable angle welding (30°–180°) available on each head as an option.

| Specification | Details |

|---|---|

| Input Voltage | 1N~50Hz 220V or Customer Specification |

| Input Power | 7 kW |

| Operation Air Pressure | 0.5~0.8 MPa |

| Air Consumption | 270 L/min |

| Welding Height | 20–130 mm |

| Welding Width | 120 mm |

| Welding Range | 400–4500 mm |

| Overall Dimension | 4600 × 1100 × 1200 mm |

| Machine Weight | 1300 kg |

| Component | Brand / Origin |

|---|---|

| 🔁 Motion & Drive Components | |

| PLC | Omron (Japan) |

| Square Bearing System | Linear (South Korea) |

| Linear Bearing System | Linear (South Korea) |

| 💨 Pneumatic System | |

| Solenoid Valve | AirTAC (Taiwan) |

| Cylinder | AirTAC (Taiwan) |

| Air Filter Device | AirTAC (Taiwan) |

| ⚡ Electrical & Control | |

| Electrical Button and Switcher | Schneider (France) |

| AC Contactor and Circuit Breaker | Schneider (France) |

| Approach Switcher | CONTRINEX (Switzerland) or Omron (Japan) |

| Temperature Controller | Omron (Japan) |

Experience the HTWA3 in Action

Experience the HTWA3 UPVC Window Three Head Welding Machine—engineered for precise and reliable welding solutions. See how it delivers consistent, high-quality joints with efficiency and ease, elevating your window manufacturing process through innovative technology and superior craftsmanship.