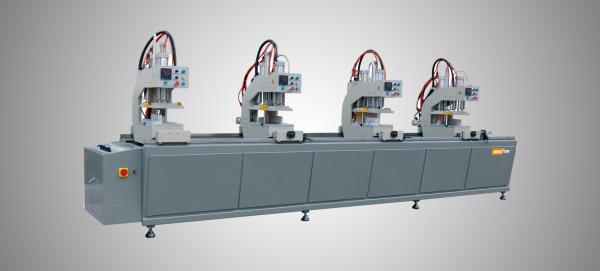

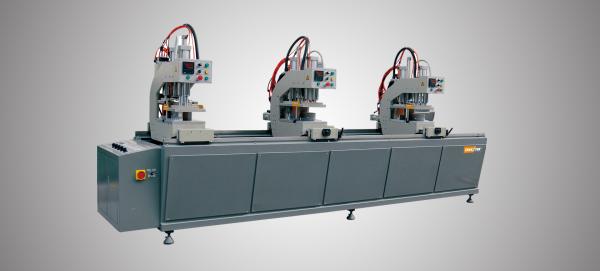

HTWA4

UPVC Window Four Head Welding Machine

The HTWA4 UPVC Window Four Head Welding Machine is a high-performance solution designed for precision welding in large-scale UPVC window production. Built to meet the standards of premium European fabrication lines, this machine offers seamless 0.2mm and 2mm welding transitions, enhanced V-welding capability, and consistent corner strength. Engineered with advanced square bearing systems and a solid machine base, the HTWA4 delivers superior accuracy, minimal welding loss, and reliable long-term performance. Ideal for high-end manufacturers seeking speed, precision, and production flexibility.

Advanced European-style four-head welding machine tailored for high-end UPVC window production.

Seamless switching between 0.2mm and 2mm welding via user-friendly selector.

Specially designed for effortless V-welding and cross-welding, eliminating the need for complex adjustments.

Automatic turret adjustment enables quick V-welding position changes for various mullion types.

Optional variable-angle welding (30° to 180°) available on the final welding head.

Robust clamping and profile positioning system ensures minimal welding deformation and high accuracy.

V-shaped heating plate provides excellent corner strength and low dimensional tolerance.

Imported square bearing system ensures precision movement of clamps, heating plates, and positioning plates.

Heavy-duty machine base provides long-lasting structural stability and dimensional precision.

Compatible with a wide range of profile heights via interchangeable fixtures (sold separately).

Two-handed safety control mechanism for operator protection.

Pneumatic brake system for safe and stable operation.

| Specification | Details |

|---|---|

| Input Voltage | 1N~50Hz 220V or Customer Specification |

| Input Power | 7 kW |

| Operation Air Pressure | 0.5~0.8 MPa |

| Air Consumption | 270 L/min |

| Welding Height | 20–130 mm |

| Welding Width | 120 mm |

| Welding Range | 370–4500 mm |

| Overall Dimension | 5600 × 2000 × 1200 mm |

| Machine Weight | 1900 kg |

🔁 Motion & Drive Components

| Component | Brand / Description |

|---|---|

| PLC | Omron |

| Approach Switcher | Swiss CONTRINEX or Japan Omron |

| Linear Bearing System | Linear (South Korean brand) |

| Square Bearing System | Linear (South Korean brand) |

💨 Pneumatic System

| Component | Brand / Description |

|---|---|

| Solenoid Valve | Airtac |

| Cylinder | Airtac |

| Air Filter Device | Airtac |

⚡ Electrical & Control

| Component | Brand / Description |

|---|---|

| Electrical Button and Switcher | Schneider |

| AC Contactor and Circuit Breaker | Schneider |

| Temperature Controller | Japan Omron |

Experience the HTWA4 in Action

Discover the HTWA4 UPVC Window Four Head Welding Machine—designed for unmatched precision and efficiency in window fabrication. Witness seamless, high-quality welds that ensure durability and perfection in every frame, driven by advanced welding technology for superior craftsmanship.