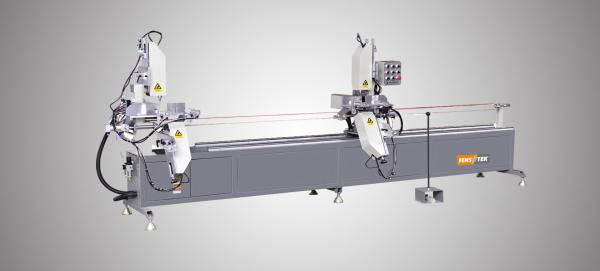

MHD4-5000

Multi-drilling Machine For PVC Window Processing

The MHD4-5000 is a high-performance multi-drilling machine designed for precision drilling of UPVC window and door profiles. Engineered for efficiency, it supports multiple drilling heads for simultaneous processing, ensuring rapid throughput without compromising accuracy. With hydraulic feeding and PLC control, this system delivers consistent performance for large-scale fabrication workshops and is adaptable to a variety of processing needs.

Specially designed for drilling installation and mounting holes in UPVC window and door profiles.

Multiple drilling heads can be configured for simultaneous multi-group hole processing.

Equipped with hydraulic cylinders to guarantee smooth and stable feeding during operation.

Advanced PLC control system allows for flexible use—each head can operate independently or in combination.

| Specification | Details |

|---|---|

| Input Voltage | 380V 50Hz |

| Input Power | 4 × 0.75kW |

| Max Processing Diameter | 13mm |

| Max Distance Between Two Holes | 5000mm |

| Min Distance Between Two Holes | 300mm |

| Working Table Dimension | 300 × 300mm |

| Drilling Bits Feeding | 125mm |

| Operation Air Pressure | 0.5 ~ 0.8MPa |

| Max Processing Section | 250 × 250mm |

| Overall Dimension | 5500 × 1000 × 1900mm |

Experience the MHD4-5000 in Action

Designed for high-output fabrication, the MHD4-5000 Multi-drilling Machine delivers synchronized, multi-point drilling for PVC window profiles. Watch it cut downtime and boost accuracy — perfect alignment, every cycle, every time.