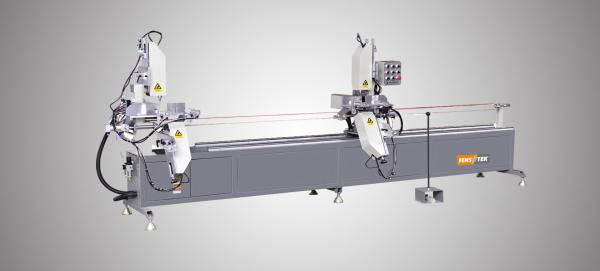

ASD-6000

UPVC Window CNC Screwing And Drilling Machine

The ASD-6000 CNC Screwing and Drilling Machine is a high-performance solution designed for precision screw insertion and drilling operations in UPVC window profiles. Combining advanced automation with robust components, it enables simultaneous screwing and drilling, dramatically enhancing assembly speed and accuracy. Ideal for reinforcement fixing and mounting hole creation, it supports seamless integration into ERP systems and offers scalable options such as custom fixtures and light curtains for optimal safety and efficiency.

Specifically designed for screwing into metal reinforcement profiles and drilling installation holes in UPVC window frames.

Dual-function system combines screw insertion and hole drilling in one operation with evenly distributed spacing and precise alignment.

Equipped with a high-reliability German POWERSURT machine head for consistent performance.

High-speed, accurate positioning through imported rack and pinion drive system.

Dual work zones allow continuous operation, enabling placement of 4 profiles per zone without halting production.

Operated via a Schneider control system built on Windows 7, with ERP software integration for real-time data exchange.

Optional light curtain enhances operational safety and user protection (available upon request).

Custom fixtures can be configured to match specific production requirements.

| Specification | Details |

|---|---|

| Input Voltage | 380V 50Hz |

| Air Consumption | 0.6–0.8 MPa (Double Air) |

| Power | 4 kW |

| Processing Range | 6000 mm |

| Double Work Table | 3000 mm × 2 |

| Screw Drive Range | 6000 × 370 × 125 mm |

| Drilling Range | 6000 × 370 mm (Adjustable height based on drilling blade length) |

Experience the ASD-6000 in Action

Boost efficiency and assembly precision with the ASD-6000 — a fully automated CNC Screwing and Drilling Machine designed for UPVC windows. Watch as it delivers synchronized drilling and screw-fastening with exact alignment, speed, and repeatability across every frame.