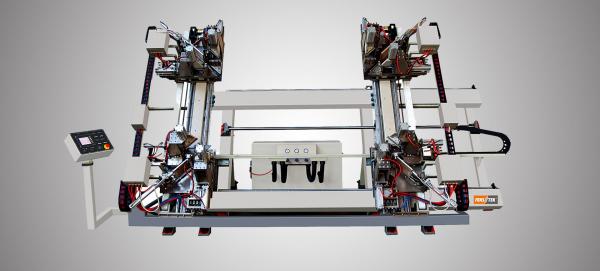

AHW6000

UPVC Window CNC Horizontal 6 Point Welding Machine

AHW6000 CNC Horizontal 6 Point Welding Machine is a high-grade, fully automatic solution designed for large-scale uPVC window production. Capable of simultaneously welding six corners, including two mullions, it delivers exceptional efficiency and dimensional precision. With advanced IPC control, world-renowned servo systems, and a rigid mechanical structure, the AHW6000 ensures consistent welding strength and seamless integration into smart production lines. This model is ideal for manufacturers seeking superior speed, accuracy, and expandability in their window fabrication process.

Designed for high-volume uPVC window manufacturing, with simultaneous 6-point welding including two mullions.

Equipped with five servo-driven axes and ball screw transmission for precise and stable motion control.

Square linear bearing systems ensure accurate clamping, heating, and locating operations.

Integrated with an advanced IPC-based control platform for intuitive operation, high precision, and system longevity.

Automatic positioning and size compensation powered by internationally recognised servo motors.

Simplified profile loading and automatic offloading enhance workflow efficiency.

Proprietary welding technology ensures superior corner strength and structural integrity.

Modular machine base design supports extended welding ranges and oversized window frame fabrication.

| Specification | Details |

|---|---|

| Input Voltage | 3N~50Hz 380V/220V or Customer specification |

| Input Power | 9 kW |

| Operation Air Pressure | 0.4~0.6 MPa |

| Air Consumption | 300 L/min |

| Welding Height | 20–160 mm / 25–70 mm |

| Welding Width | 120 mm / 65 mm |

| Welding Range | 500×500 – 2800×2600 mm |

| Overall Dimension | 4100×4500×2190 mm |

| Machine Weight | 4000 kg |

| Component | Brand / Origin |

|---|---|

| 🔁 Motion & Drive Components | |

| Controlling System | Schneider or equivalent international brand |

| Servo Motor | Schneider or equivalent international brand |

| Linear Bearing System | South Korean Brand |

| 💨 Pneumatic System | |

| Solenoid Valve | AirTAC (Taiwan) |

| Cylinder | AirTAC (Taiwan) |

| Air Filter Device | AirTAC (Taiwan) |

| ⚡ Electrical & Control | |

| Electrical Button and Switcher | Schneider (France) |

| AC Contactor and Circuit Breaker | Schneider (France) |

| Approach Switcher | Swiss CONTRINEX or Japan Omron |

| Temperature Controller | Omron (Japan) |

Experience the AHW6000 in Action

Meet the AHW6000 – the CNC Horizontal 6 Point Welding Machine designed for precision UPVC window fabrication. Engineered for high-speed, high-strength welding, it delivers consistent, clean joints across complex profiles with industrial-grade efficiency and reliability.