Insulating Glass Processing Machine

Insulating Glass Machine is used for processing the glass.

Insulating Glass Production Line

Insulating Glass Production Line: Insulating Glass Production Line

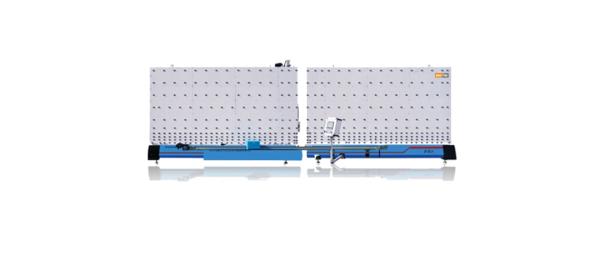

ZDJ-V20

Automatic sealing robot

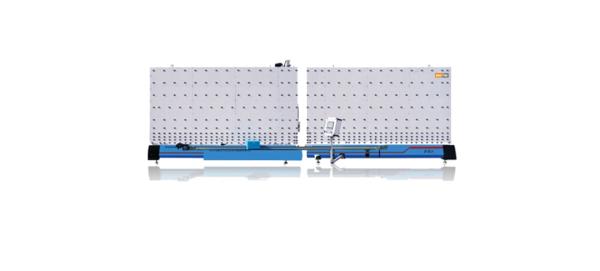

ZDJ-V25

Automatic sealing robot

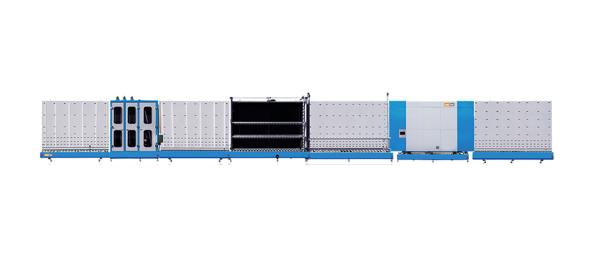

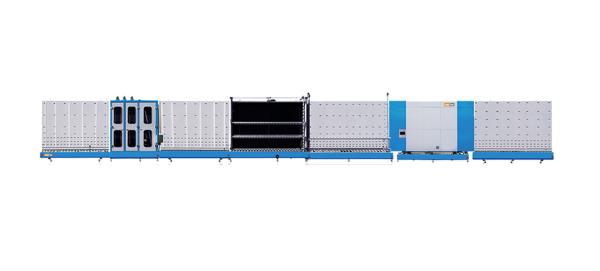

LBP2000Q

Gas Filling model - Vertical Insulating Glass Production Line

LBP2500Q

Gas Filling model - Vertical Insulating Glass Production Line

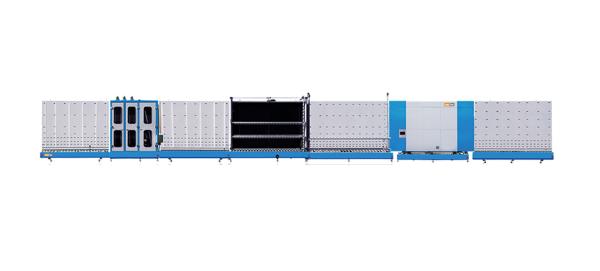

LBP2500

Fast model - Vertical Insulating Glass Production Line

LBP2000

Fast model - Vertical Insulating Glass Production Line

Auxiliary Machine

Insulating Glass Production Line: Insulating Glass Production Line

Insulating Glass Processing Machine

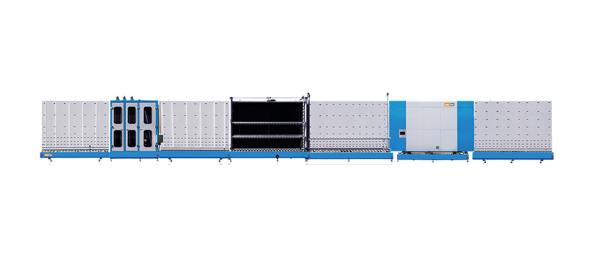

Insulating Glass Machine is used in the production of insulating glass. It can automatically detect the coated side of coated glass and Low-E glass, with an alarm indicating the detection.

The washing section uses stainless steel and other corrosion-resistant materials, ensuring excellent waterproofing, safety, cleanliness, and long service life. It is equipped with a sponge roller, which improves the efficiency of both washing and drying.

The machine supports both inner-panel and outer-panel assembly functions and is capable of producing double- and triple-glazed insulating glass with the same edge structure, offering high production efficiency.

When using the inner-panel assembly function, the system can fill the insulating glass unit with inert gas.

The gluing section adopts a specially designed positioning mechanism to ensure that the gluing nozzle contacts the IG unit closely without causing damage. It can also accommodate a certain range of positioning errors in the IG unit.