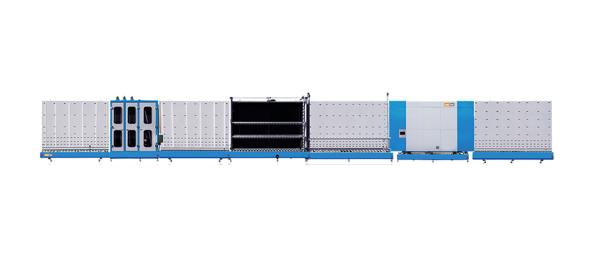

LBP2500Q

Gas Filling model - Vertical Insulating Glass Production Line

LBP2500Q Gas Filling Vertical Insulating Glass Production Line is a high-performance, fully automated solution for efficient insulating glass (IG) unit production. Specially engineered to handle both double and triple glazed units, this advanced production line integrates glass washing, inert gas filling, and panel assembly processes with precision and ease. Featuring intelligent PLC controls, top-brand components, and automated sealing functionality, the LBP2500Q ensures high throughput, excellent sealing quality, and reduced operational error—making it the ideal solution for large-scale IG manufacturing operations.

Automatically detects the coated side of coated or Low-E glass and triggers an alarm for accurate orientation.

The washing section is constructed from stainless steel and corrosion-resistant materials for enhanced durability, safety, and longevity—equipped with sponge rollers for more efficient washing and drying.

Supports both inner-panel and outer-panel assembly, enabling high-efficiency processing of same-edge double and triple-glazed IG units.

Enables inert gas filling during inner-panel assembly for improved insulation performance.

Equipped with world-renowned low-voltage electrical components, sensors, and PLC for extended service life and operational stability.

PLC-controlled touchscreen interface allows intuitive operation and advanced fault self-diagnosis for superior automation.

The press section opens up to 500mm for easy maintenance; the drying section uses a hot air circulation system for effective drying and low noise.

Built-in glass position memory function simplifies correction of positioning errors, enhancing productivity and efficiency.

| Specification | Details |

|---|---|

| Power Supply | 220V 60HZ or customer specification |

| Single Glass Thickness | 3 – 15 mm |

| Washing Speed | 3 – 15 m/min |

| Drying Speed | 3 – 9 m/min |

| IG Thickness | 12 – 50 mm |

| Work Speed | 15 – 45 m/min |

| Minimum IG Unit Size | 450 x 200 mm |

| Maximum IG Unit Size | 3600 x 2500 mm |

| Standard Height | 400 mm |

| Angle of Inclination | 6° |

| Air Pressure | 0.6 – 0.8 MPa |

| Total Power | 44 kW (including 10 kW heater) |

| Machine Weight | 8500 kg |

| Contour Dimension | 24000 × 2500 × 3680 mm |

| Component | Brand / Origin |

|---|---|

| 💨 Pneumatic System | |

| Solenoid Valve | Airtac (Taiwan) |

| Cylinder | Airtac (Taiwan) |

| Air Filter Device | Airtac (Taiwan) |

| ⚡ Electrical & Control | |

| PLC | Delta (Taiwan) |

| Inverter | Delta (Taiwan) |

| Electrical Button and Switcher | Delixi (China) |

| AC Contactor and Circuit Breaker | Delixi (China) |

| Approach Switcher | Delixi (China) |