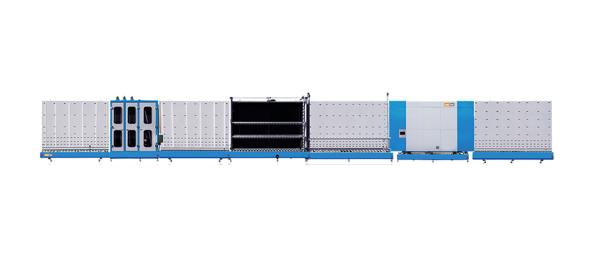

LBP2000

Fast model - Vertical Insulating Glass Production Line

The LBP2000 Fast Model Vertical Insulating Glass Production Line is designed for high-efficiency assembly of double-glazed insulating glass units. This intelligent system features automatic coating side detection, a stainless steel washing section, and integrated energy-saving mechanisms. Built with globally renowned electrical components and PLC control, it delivers reliable performance, extended service life, and excellent ease of operation. With automated fault diagnostics, hot air drying, and a memory function for glass positioning, this machine significantly enhances production speed, quality, and operator convenience.

Automatically detects and alerts for the coating side of coated or Low-E glass.

Washing section made of stainless steel and anti-corrosive materials for longevity and safety.

Efficient processing of double-layer insulating glass with same-edge configuration.

Equipped with globally recognised low-voltage electrical components and sensors for durability.

PLC control system with touch screen interface for intuitive operation and fault self-diagnosis.

Large-opening press section (up to 500mm) ensures easy access for maintenance.

Hot air circulation drying section ensures low-noise, high-quality drying.

Glass position memory function reduces operational errors and improves efficiency.

Auto power-off feature helps conserve energy during downtime.

Includes an aluminium spacer suspension system as standard.

Advanced pressing mechanism ensures perfect parallelism for optimal sealing.

| Specification | Details |

|---|---|

| Power Supply | 220V 60Hz or customer specification |

| Single Glass Thickness | 3 – 15 mm |

| Washing Speed | 3 – 15 m/min |

| Drying Speed | 3 – 9 m/min |

| Insulating Glass Thickness | 12 – 50 mm |

| Working Speed | 15 – 45 m/min |

| Minimum IG Unit Size | 450 × 200 mm |

| Maximum IG Unit Size | 3000 × 2000 mm |

| Standard Height | 400 mm |

| Inclination Angle | 6 degrees |

| Air Pressure | 0.6 – 0.8 MPa |

| Total Power | 44 kW (including 10 kW heater) |

| Machine Weight | 8500 kg |

| Contour Dimensions | 22800 × 2500 × 3180 mm |

| Component | Brand / Origin |

|---|---|

| 🔁 Motion & Drive Components | |

| Inverter | Delta |

| 💨 Pneumatic System | |

| Solenoid Valve | AirTAC (Taiwan) |

| Cylinder | AirTAC (Taiwan) |

| Air Filter Device | AirTAC (Taiwan) |

| ⚡ Electrical & Control | |

| PLC | Delta |

| Electrical Button & Switcher | Delixi |

| AC Contactor & Circuit Breaker | Delixi |

| Approach Switcher | Delixi |