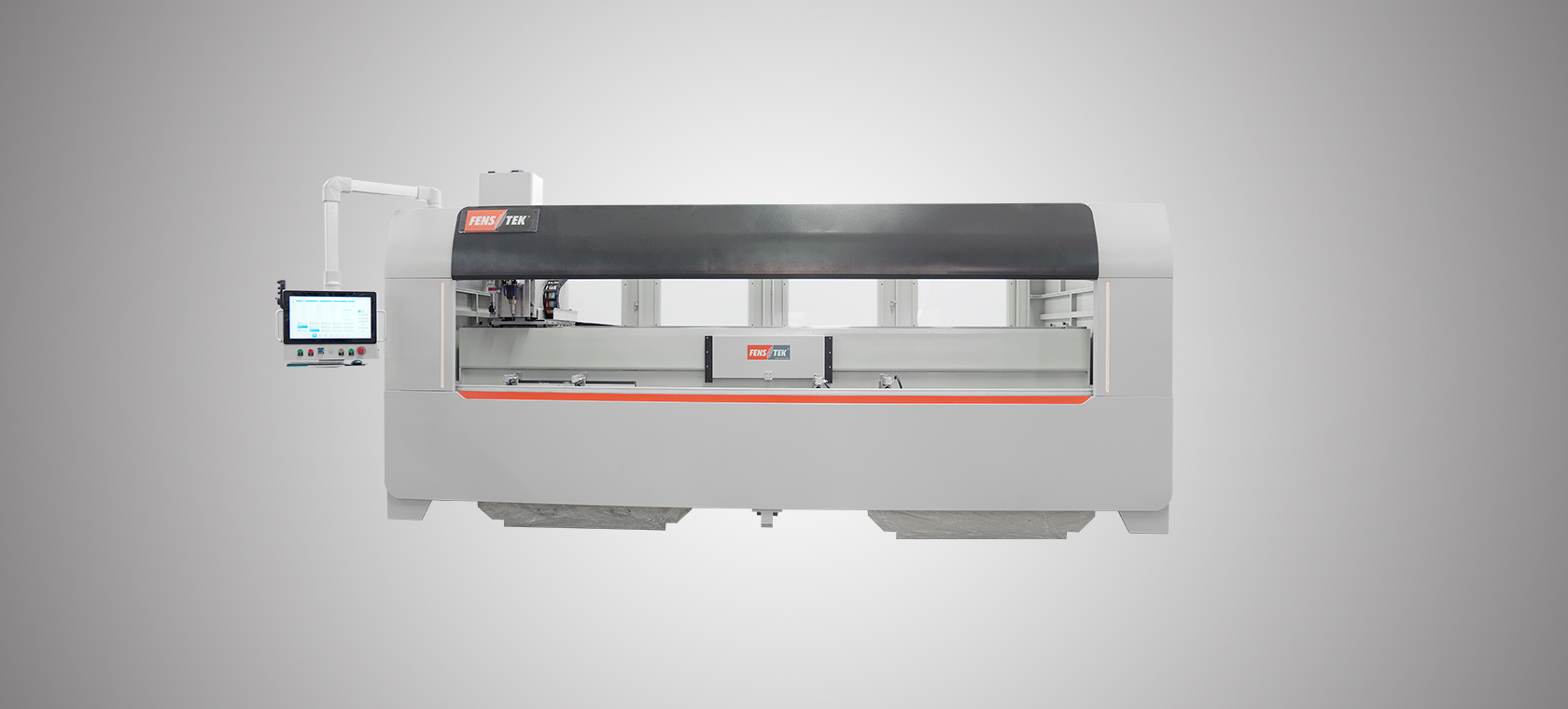

Emerald T300

Aluminium Facade Three-axis Machining Centre

The Emerald T300 is a precision 3-axis CNC machining centre designed for processing aluminium façades, uPVC, and light alloy profiles. With automatic tool changing, dual working zones, and high-speed multi-function machining, it offers exceptional productivity for curtain wall, door, and window fabrication. Its robust gantry structure and ERP integration make it ideal for modern, high-volume manufacturing.

Advanced 3-axis CNC machining centre designed for aluminium façade profiles and light alloy processing

Suitable for aluminium, uPVC, and other lightweight industrial profiles

Performs milling, drilling, tapping, grooving, and light steel drilling in a single cycle

Stationary profile conveyance system prevents movement and ensures precision during operation

Built with high-precision imported linear guideways, ball screws, gear racks, and servo motors for smooth, accurate motion

Equipped with an automatic tool changer featuring a travelling magazine for reduced tool change time and low noise

Supplied with a 6-position tool magazine and adjustable pneumatic fixtures for efficient profile handling

Dual working zones allow alternate loading and machining for uninterrupted, non-interfering operation

Integrated multi-layered safety systems to protect the operator during high-speed processes

Operated via an industrial PC based on Windows® with a user-friendly interface and remote troubleshooting

Supports USB input, CAD file import, and manual programming directly on the control system

ERP system integration enabled with optional barcode scanning and automatic processing

Gantry-type welded steel structure with heat ageing and annealing treatment ensures long-term rigidity and stability

Includes UPS and air-conditioning unit to safeguard the control system and maintain consistent performance

Optional processing lengths available: 4 m, 8 m, 10 m, or custom configurations

| Specification | Details |

|---|---|

| Air Consumption | 60 L/min |

| Input Power | 13 kW |

| Power Specification | 3N~50Hz 380V (or customised) |

| Air Pressure | 0.5 – 0.8 MPa |

| X-axis Feed Rate | 0 – 60 m/min |

| Y-axis Feed Rate | 0 – 30 m/min |

| Z-axis Feed Rate | 0 – 30 m/min |

| Spindle Speed / Power | 0 – 24,000 rpm / 7.5 kW |

| Tool Magazine | 6 tool positions |

| Diameter of Blade | Ø80 – Ø150 mm |

| Cutting Tool Installation Length | 135 mm |

| Clamp Stations | 8 |

| Processing Range (Standard Clamp) | 7000 × 500 × 300 mm |

| Processing Range (Special Clamp) | 7000 × 800 × 300 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeat Positioning Accuracy | ±0.02 mm |

| Cutting Surface Roughness | Ra ≤ 12.5 µm |

| Machine Dimensions (L × W × H) | 9000 × 1800 × 2150 mm |

| Weight | 4300 kg |

| Component | Brand / Origin |

|---|---|

| 🔁 Motion & Drive Components | |

| CNC System | PA (Germany) |

| Servo Motor | Yaskawa (Japan) |

| Reducer | APEX (Taiwan) |

| Spindle | HSD (Italy) |

| Square Guide Rail | HIWIN (Taiwan) |

| Ball Screw | PMI (Taiwan) |

| Rack | APEX (Taiwan) |

| 💨 Pneumatic System | |

| Air Cylinder | AirTAC (Taiwan) |

| ⚡ Electrical & Control | |

| Buttons & Switches | Schneider (France) |

Experience the Emerald T300 in Action

Unleash precision and efficiency with the Emerald T300 Aluminium Facade Three-axis Machining Centre. Master complex profiles for windows, doors, and facade systems, achieving flawless results with advanced CNC automation and robust engineering.