KDT KN-2409DL/2409NL Flat Bed CNC Router

Combining professionalism with affordability, our system offers a table size of 2860mm x 1260mm. Featuring a 12 linear tool capacity and a 10 spindle drill head option, it boasts a powerful spindle and gantry setup for optimal performance. Enjoy added convenience with auto nest push-off functionality, along with safety features including a fence and auto shutoff beams. Pricing from $48.950 + GST

- 2840mm x 1250mm bed size

- With and without Drill Head options

- 2860mm x 1840mm bed size also available

Features

Also available with 10 Spindle Drill Head – KN-2409DL

Technical Data

| Working area of Y and X axes | 2850 mm x 1220 mm |

| Max Traverse speed | 100 m/min X and Y |

| Capacity of vacuum pump | 1 x 244 m³/hr |

| Automatic tool height measuring | Standard inclusion |

| Transmission for X and Y axis | Helical rack and pinion |

| Transmission for Z axis | Ball screw at 30 m/min |

| Air cooled spindle – 3000-21,000 | 12 hp |

| Auto linear Toolchange | 12 position Linear |

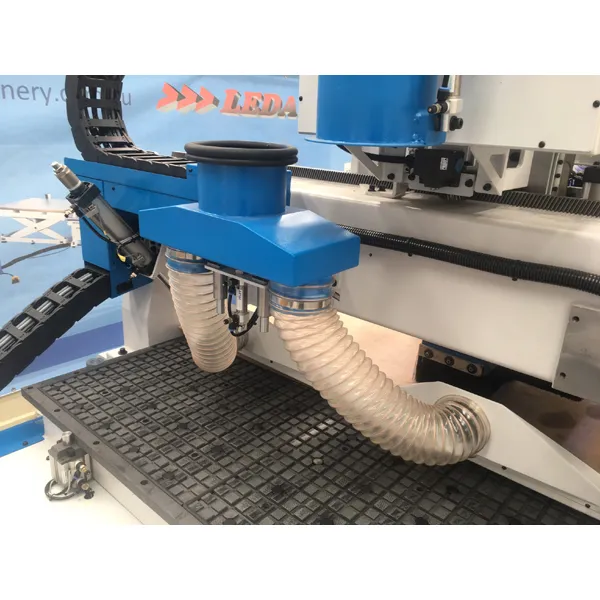

| Dust hood connection diameter | 150 mm |

See the KN 2409NL in Action

Strong and reliable vacuum

Poor vacuum frustrates the operator with wasted panels and time.

Superior table design with a large very open vacuum chamber area that is part of the machine frame and significantly improves vacuum distribution.

7 vac zones

– selected from the front of the machine.

The pneumatic stops have safety sensors should a stop not retract.

Auto nest push off – a huge productivity boost.

Smart unloading pusher with built in extraction moves your completed nest to a sorting table. You can immediately load a new panel and commence your next nest and effectively double your output.

We can supply a simple static table – or KDT have a clever driven outfeed table option with extraction and light sensor control – perfect if using JIT labelling.

Superior Gantry design

Fast X and Y positioning.

Gantry is supported and driven on both sides of the X axis > eliminates gantry sag while providing superior accuracy with greatly reduced vibration. This in turn delivers faster cleaner routing improving finish and dimensional accuracy.

The guides are lubricated from a centralised oiling system.

The best drives, guides and cables

The gantry is driven by 2 powerful Servo drives electronically linked driving the gantry and machining group along heavy duty 30mm helical rack and pinion systems . This ensures rack teeth are engaged fully at all times> delivers smooth acceleration and deceleration, increased accuracy with significantly reduced vibration and noise.

Z axis drive is via a central recirculating ball screw and twin widely spaced linear guides for smooth, precise and quiet positioning

German flexible cables are used for their proven reliability in this high wear area.

Linear tool change

Powerful Electro Spindle

12HP air cooled Electro Router spindle has step-less control from 3,000 to 21,000 rpm max by a Inverter. You can always program the correct rotation speed of any tool for the optimum routing and drilling results.

Our have a well-earned reputation for Quality and longevity and every mechanical, pneumatic and electronic component undergoes a rigorous double testing program.

Dust extraction is important