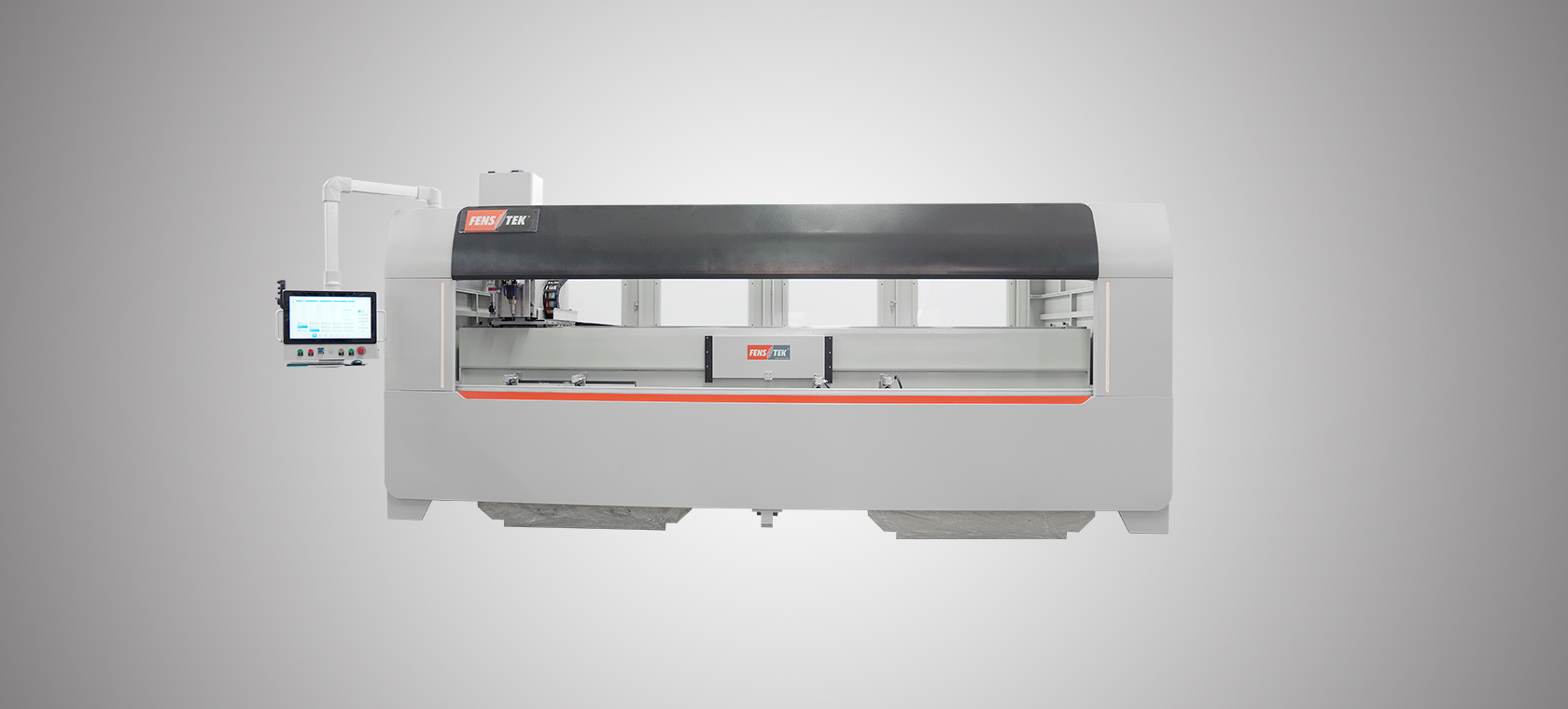

Emerald F550

Aluminium Facade Five-axis Machining Centre

The Emerald F550 is a high-performance 5-axis CNC machining centre engineered for advanced processing of aluminium, steel, and uPVC façade profiles. Designed for complete multi-surface machining in one clamping, it features dual working zones, automatic tool change, and ERP system integration. With precision motion control and a robust gantry structure, the F550 ensures exceptional accuracy, reliability, and efficiency in high-volume architectural fabrication.

Advanced 5-axis CNC machining centre designed for aluminium façade, window, and door profile fabrication

Suitable for machining aluminium, steel, and uPVC profiles with high precision and flexibility

Performs sawing, milling, drilling, tapping, thread drilling, and angle notching on all surfaces except the bottom in a single clamping cycle

Gantry-type construction with a moving beam and moving column for enhanced machining rigidity and stability

Profile clamping system minimises surface damage and eliminates repositioning errors

Equipped with high-end imported CNC control system: Siemens (Germany) or OSAI (Italy)

Built with premium imported components, including servo motors, ball screws, linear guides, and bearings to ensure long-term accuracy and reliability

Feeding mechanism is pre-stretched to maintain consistent machining precision over time

Moving tool magazine reduces tool change time and includes one additional 500 mm saw blade

Pneumatic clamping worktable accelerates loading/unloading and enhances operational efficiency

Dual working zones allow alternate profile loading and machining for continuous, high-output production

Built-in safety protection functions to ensure operator safety during high-speed operation

ERP integration supported with optional barcode scanning and automatic processing

Includes UPS and air-conditioning unit to safeguard the control system and ensure uninterrupted performance

| Specification | Details |

|---|---|

| Power Supply | 3N~50Hz 380V (or customised) |

| Total Power | 28 kW |

| Air Pressure | 0.5 – 0.8 MPa |

| Air Consumption | 50 L/min |

| Spindle Power / Speed | 12 kW / 24,000 rpm |

| Spindle Taper | HSK-63F |

| X-axis Stroke | 7000 mm |

| Y-axis Stroke | 1000 mm |

| Z-axis Stroke | 550 mm |

| B-axis Rotation Range | ±185° |

| C-axis Rotation Range | ±320° |

| X-axis Moving Speed | 0 – 60 m/min |

| Y-axis Moving Speed | 0 – 30 m/min |

| Z-axis Moving Speed | 0 – 30 m/min |

| B-axis Working Speed | Max. 7°/sec |

| C-axis Working Speed | Max. 7°/sec |

| Tool Magazine Type | Carousel type |

| Tool Magazine Capacity | 11 tools |

| Lubrication / Cooling System | Automatic lubrication / Micro atomisation cooling |

| Machine Dimensions (L × W × H) | 9500 × 3000 × 2500 mm |

| Weight | 11,000 kg |

| Component | Brand / Origin |

|---|---|

| 🔁 Motion & Drive Components | |

| CNC System | Siemens (Germany) or OSAI (Italy) |

| Servo Motor | Yaskawa (Japan) |

| Reducer (X-axis) | APEX (Taiwan) |

| Spindle | HSD or Hiteco (Italy) |

| Square Rail | HIWIN (Taiwan) |

| Ball Screw | PMI (Taiwan) |

| Rack | APEX (Taiwan) |

| 💨 Pneumatic System | |

| Electromagnetic Valve | AirTAC (Taiwan) |

| Pressure Switch | AirTAC (Taiwan) |

| Air Cylinder | AirTAC (Taiwan) |

| Spindle Air Source Drying Filter | SMC (Japan) |

| Spindle Supercharger | SMC (Japan) |

| ⚡ Electrical & Control | |

| Buttons & Switches | CONTRINEX (Switzerland) or Omron (Japan) |

| Low-Voltage Apparatus | Schneider (France) |

| Connecting Terminals | Weidmüller (Germany) |

Experience the Emerald F550 in Action

Experience the apex of precision engineering. Our Emerald F550 Aluminium Facade Five-axis Machining Centre masters the most intricate profiles for windows, doors, and advanced facade systems, delivering unmatched quality and efficiency through simultaneous five-axis control.