S300

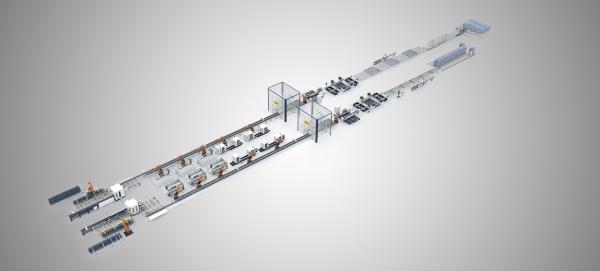

Fully Automatic Robot Window and Door Production Machine Line

The S300 is a fully automated robotic production line engineered for window and door manufacturing. Designed to streamline high-volume fabrication, it integrates robotics, smart logistics, and CNC operations to perform profile handling, precision cutting, drilling, assembling, and material transfer in a single system. It is ideal for manufacturers seeking to modernise their production with minimal labour and maximum efficiency.

Fully automated production line for window and door manufacturing

Integrated robotic arm for profile handling and workstation transfer

SLAM-based navigation for precise, rail-free movement within tight factory spaces

Dual LiDAR and vision system enables 360° obstacle avoidance and spatial awareness

Compact design with minimal aisle clearance requirements (as low as 30 mm)

Operates without fixed-site infrastructure or guide rails

Quick deployment—ready for production within 5 to 7 working days

Automatic charging function enables 24/7 autonomous operation

Intelligent scheduling software supports fleet coordination and real-time task distribution

Compatible with MES, ERP, and WMS systems for full digital integration

Multi-language interface with English and Chinese support

Modular configuration allows easy integration with conveyors, robotic arms, and lifts

Built-in LED status indicators and voice prompts for system alerts and user guidance

Customisable robotic modules for different production needs

Collision protection with emergency stop buttons and safety bumpers

Capable of handling aluminium and other light industrial profiles

High payload capacity of up to 300 kg for efficient material handling

Designed for long-term use in industrial environments with minimal maintenance

Suitable for Industry 4.0 smart factory environments

| Specification | Details |

|---|---|

| Dimensions (L × W × H) | 820 × 580 × 316 mm |

| Net Weight | 135 kg |

| Maximum Payload | 300 kg |

| Travel Speed | Up to 1.5 m/s |

| Positioning Accuracy | ±10 mm |

| Minimum Aisle Clearance | 30 mm |

| Slope Capability | Up to 5% |

| Battery Type | Lithium iron phosphate (LiFePO₄), 48 V / 30 Ah |

| Battery Runtime | 6–8 hours (supports automatic charging) |

| Charging Modes | Automatic docking, manual, or hot swap |

| Communication | Wi-Fi 2.4 / 5 GHz |

| Operating Temperature | 5–40°C |

| Relative Humidity | 10–95% RH (non-condensing) |

| Ingress Protection | IP20 |

| Certifications | CE, EN ISO 3691-4:2023, EN 60204-1, EN 1175 |

| Component | Brand / Origin |

|---|---|

| 🔁 Motion & Drive Components | |

| Differential Drive Chassis | Custom Industrial (China) |

| Servo Motor & Drive Unit | DELTA (Taiwan) or Equivalent |

| Precision Drive Wheels | High-Grip PU Coated (China) |

| Motor Control System | Innovix OEM Controller (China) |

| 👁️ Vision & Navigation | |

| LiDAR Sensors (x2) | Sick (Germany) or Hokuyo (Japan) |

| 3D Vision Camera | Intel RealSense (USA) |

| Navigation Algorithm | Fusion SLAM (LiDAR + Vision) – Innovix (China) |

| 💨 Pneumatic System | |

| Pneumatic Actuation Components | AirTAC (Taiwan) |

| Profile Clamping Mechanism | Custom-Built (China) |

| ⚡ Electrical & Control | |

| Main Control System | Industrial PC with Windows® OS (Custom OEM) |

| Low-Voltage Apparatus | Schneider Electric (France) |

| Battery Pack | LiFePO₄ 48V / 30Ah (China) |

| Charging Station | Auto Dock Type (OEM, China) |

| 🧠 Software & Integration | |

| Fleet Scheduling Software | InnovixBot Fleet Manager (China) |

| System Integration | Compatible with ERP / MES / WMS platforms |

| User Interface | Touchscreen with English/Chinese Voice Guidance |

Experience the S300 in Action

Experience peak performance with the S300 Fully Automatic Robot Window and Door Production Machine Line. Achieve precise, high-volume production of windows and doors through advanced robotic automation.